RAW MATERIALS

Due to our longtime experience as manufacturer of glazes, frits and colours we know about the importance of a reliable and stable supply of raw materials. The selection of raw materials represents the basis for competitive final products. We always focus on the requirements for our production and our customers.

Floorextiles offers our clients the following raw materials:

- Alumina

- Ball Clay

- Barium Carbonate

- Bentonite

- Calciumd Oxide

- Cerium Oxide

- Chromium Oxide

- Clay

- Cobalt Oxide

- Dolomite

- Iron Oxide

- Kaolin

- Lithium Feldspar

- Magnesium Oxide

- Nepheline Syenite

- Nickel Oxide

- Potassium Feldspar

- Potassium Nitrate

- Quartz

- Silica Flour

- Sodium Carbonate

- Sodium Feldspar

- Synthetic Micas

- Talcum

- Tin Oxide

- Titanium Dioxide

- Wollastonite

- Zinc Oxide

- Zirconium Silicate

Zircon Opacifiers & Zircon Flour

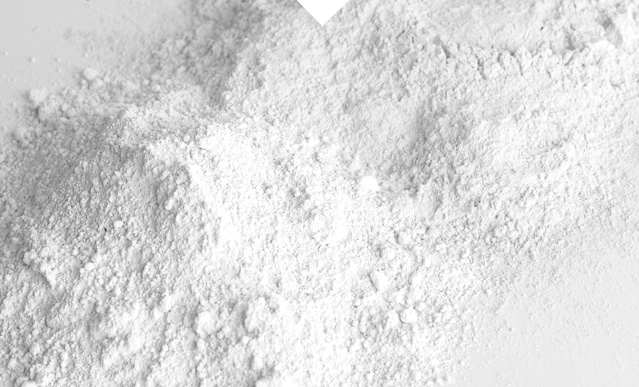

Floorextiles offer high quality of its opacifiers MICROZIR© obtained by the use of premium zircon sand and the latest technology in ultra-fine grinding.

The ceramic opacifier MICROZIR© provides high whiteness and opacity in ceramic glazes, ceramic pigments, porcelain bodies, sanitaryware and tableware.

For specific applications, such as sanitaryware, we offer MICROZIR© finer and white zircon opacifiers.

The zircon flour MICROZIR© is used by various industrial sectors such as manufacture of frits, brake lining, foundry, glass, investment casting and refractory.

FRITS & GLAZES

Frits are the main component of nearly all ceramic glazes and are present in many compositions of different materials where a glass face is needed, even if only as a binder. The multiple applications, and various baking methods of the products which are used, under different names, have made it so that over the years the Frits family has gained numerous members, many of them very different between themselves.

A Glaze is usually made up of one or more frits with the addition of, where necessary, raw materials, pigments, salts, etc.

The complete composition which takes the name of composite glaze, or just composite is ready to by milled, usually in a ball mill, with water and possibly additives to stabilize the resulting semi liquid mass.

Based on frits, and the additives used, the effects that may be obtained are nearly infinite.

Frits & glazes for single-firing (wall tile body)

Floorextiles offers a wide range of ceramic frits for single-firing temperatures (1100°c – 1160°c). Made with the highest quality raw materials, and subjected to constant, precise tests. They range from glossy frits (transparent and white), to matt (transparent and white), with hard and soft surfaces.

Frits & glazes for porcelain

We offer a wide range of ceramic frits for porcelain temperatures (1180°c – 1200°c). Made with the highest quality raw materials, and subjected to constant, precise tests. They range from glossy frits (transparent and white), to matt (transparent and white), with hard and soft surfaces.

Frits and glazes for double-firing

We offer a wide range of ceramic frits for double-firing temperatures (1000°c – 1100°c). Made with the highest quality raw materials, and subjected to constant, precise tests. They range from glossy frits (transparent and white), to matt (transparent and white), with hard and soft surfaces.

Frits & glazes for third firing

Floorextiles offers a wide range of ceramic frits for third-firing temperatures (850°c – 1000°c). Made with the highest quality raw materials, and subjected to constant, precise tests. They range from glossy frits (transparent and white), to matt (transparent and white), with hard and soft surfaces.

Frits for glass

We produce a wide range of frits used for the glass industry for temperatures from 580ºC a 700ºC.

Frits for engobes and with high c.o.e.

Remedial frits are usually used in low percentage where it is necessary to modify a glazes expansion coefficient in order to optimize the dilatometric harmony with the support. Frits for engobes are characterized by a good whitening power and a good melting property.

Reactive and special frits

These frits are characterized by their high reactivity. Their use allows for special effects, refined surfaces, and unique colours, depending on the type of raw material used.

Melting frits

These are materials which melt at low temperatures and are therefore ideal for helping to initiate chemical reactions within the glaze during firing. When used in low temperature cycles, they are optimal for amalgamating materials which melt at high temperatures.

Frits for abrasives

Floorextiles offers a wide range of frits for the abrasives industry (in particular melting and binding frits). Made with the highest quality raw materials, they may be used in many different applications between 700°c and 1300°c.

Frits for manufactured products (stoves , etc.)

We offer a wide range of special frits (majolica, crystalline, reactive,) for use in manufacturing..

Frits for construction

We have perfected, over time, a range of frits made specifically to cater to the needs of the construction industry (in particular bricks, shingles, etc.).